Search This Blog

Most Popular

Categories

- Building Construction (84)

- Building Materials (82)

- Columns (2)

- Concrete Beam (3)

- Concrete Construction Techniques (4)

- Concrete Mix Design (9)

- Concrete Repair (14)

- Concrete Slab (10)

- Construction Equipment (16)

- Construction News (7)

- Design of Structures (15)

- Engineering Drawing (1)

- Estimation (3)

- Geotechnical engineering (26)

- Highway Engineering (11)

- Innovations (30)

- Material Testing (10)

- Matrix Analysis of Structures (2)

- Mechanical Engineering (3)

- Strength of Materials (2)

- Structural Analysis (17)

- Structural Design (21)

- Structures (17)

- Transportation Engineering (9)

Fineness Test On Cement

Neenu

March 04, 2024

The fineness test of cement measures the mean size of the cement grain in the given sample. The greater the fineness value, the higher the surface area of each grain particle which results in an increase in the rate of hydration of cement, the rate of evolution of heat, and hence the rate of initial gain strength.

But, every cement grain must possess an optimum fineness value or else fine grinding makes cement susceptible to air setting. An increase in the fineness of cement also results in an increase in the drying shrinkage of concrete. Usually, the grain size of the cement particles is within 7 ~ 200 μm (0.007 ~ 0.2 mm).

Of the various physical properties that relate to cement quality, probably the most important and widely used is fineness. Because cement is a ground material, it has an inherently broad particle size distribution.

The fineness test on cement can be conducted by two methods:

- Sieve Analysis

- Air-Permeability Test

- 1. Lea and Nurse Air Permeability Apparatus

- 2. Blain Air Permeability Apparatus

The determination of fineness test by sieve analysis gives a measure of the limit of residue that is regained in a standard sieve, while the air permeability test measures the fineness of cement in terms of surface area either in g/cm2 or kg/cm2.

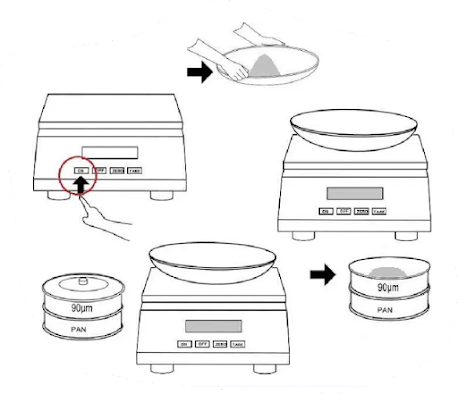

1. Sieve Test on Cement (IS:4031 (Part 1))

Weight 100 grams of cement and is sieved through a standard IS Sieve No. 9 (90 microns). Before sieving, any air-set lumps of cement are broken down with fingers. Start sieving continuously by giving circular and vertical motions for 15 minutes. If required, mechanical sieving devices may be used. Now, weigh the residue left on the sieve. Express its mass as a percentage (R1) of the quantity first placed in the sieve.

|

| Fig.1. Sieve Analysis on Cement using 90μm sieve |

Repeat the steps 3 to 5 with a fresh sample to obtain R2. If the results differ by more than 1 percent absolute, carry out a third sieving and calculate the mean of the three values.

Ravg = (R1+R2+R3) / 3

Fineness modulus of cement = Ravg/ 100

The proportion of cement of which the grain sizes are larger than the specified mesh size is thus determined.

Optimum Result: The weight of the residue left on the sieve shall not exceed 10 % for ordinary cement.

Read On:

2. Air Permeability Test on Cement

The air permeability of a material is the measure of how easily air can pass through a material. The basic principle used in the air permeability test to determine the fineness of cement is based on the relationship between the fineness of cement particles and the rate at which air can pass through a compacted cement sample.Finer particles provide greater surface area, resulting in increased resistance to airflow. Therefore, by measuring the time it takes for a fixed volume of air to pass through a cement sample under standard conditions, we can infer the fineness of the cement.

A. Lea and Nurse Air Permeability Apparatus

Lea and Nurse Air permeability Apparatus is used here to test the fineness of the cement. The test measures the specific surface of the cement. The result is expressed as the total surface area in sq. cm/gm of cement. It is also expressed in m2/kg.

|

| Fig.2. Lea and Nurse Air Permeability Apparatus |

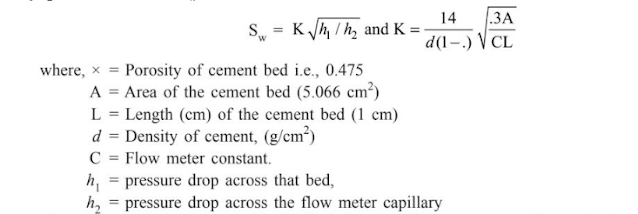

As shown in the apparatus (Figure 2), the cement bed in the permeability cell is 1 cm high and 2.5 cm in diameter. This cement bed must possess a porosity of 0.475 . The weight of cement corresponding to this porosity is calculated by knowing the density of cement and the known porosity value.

Once the quantity of cement is placed in the permeability cell in a standard manner, air is passed through the cement bed slowly at a constant velocity. The rate of airflow is adjusted until the flow meter shows a difference in level of 30 to 50 cm. Now, read the difference in level h1 in the manometer and h2 in the flow meter.

The observations are repeated until steady conditions are obtained by a constant value of h1/h2. Then, Specific Surface Sw is given by the following formula:

B. Blaine's Air Permeability Test on Cement (IS:4031 (Part 2))

Blaine's air permeability apparatus follows a means of drawing a definite quantity of air through a prepared bed of cement of definite porosity. It consists of a calibrated U-tube manometer, stainless steel test cell and plunger, rubber aspirator bulb, and perforated disc.

|

| Fig.3. Blain Air Permeability Apparatus |

Place the perforated disc at the bottom of the cell and place on it a new filter paper disc. Then place the weighed quantity of standard cement in the cell taking care to avoid loss. Tap the cell to level the cement. Place a second new filter paper disc on the leveled cement. Compress the cement with the plunger. Close the top of the cell with a suitable cork.

Attach the permeability cell to the manometer tube and slowly evacuate the air in the manometer tube using the aspirator bulb until the liquid reaches the top mark, then tightly close the valve and monitor the oil as it starts to fall. Using a stopwatch, measure the time taken for the oil to fall from the top mark to the bottom mark.

Calculate the fineness of cement using the following expression.

The value of the square root of 0.1η is determined based on Table 1 given below, as per IS:4093-PART 2.

The formula for apparatus constant is given in the table below as per IS code. Here,

- So is the specific surface of the reference cement (cm2/g)

- e is the porosity of the bed of cement under test

- t is the measured time for the cement under test(s)

- to is the mean of the three times measured on the reference cement(s), p is the density of the cement under test (g/cm”)

Result: The minimum specific surface for OPC should not be less than 2250 cm²/kg.

Conclusion

Fineness is normally expressed in Blaine (m²/ kg). It means that if 1 kg of cement is taken, the sum total of the surface area of all its particles will be so many m². In Indian cement, normally it varies between 225 to 325 m²/kg, except for cement for concrete sleepers (53-S / 43-S). Sometimes fineness is also expressed in CGS system (cm²/g), in which case the value in Blaine is multiplied by 10 and accordingly ranging between 2250 cm²/g to 3250 cm²/g.

Read More On: Cement

Most Visited

Sieve Analysis of Aggregates - ASTM Standard

August 11, 2021

What are Infiltration Wells?

April 15, 2024

How to Choose Good Quality Aggregates for Construction?

August 10, 2021

How to Calculate Cement Required for Floor Tiling?

July 02, 2020

Cross-Section of a Road – Geometric Design of Highways

February 26, 2021

Traverse Surveying - Objective, Method and Procedure

January 19, 2022

Construction ERP System – A Comprehensive Guide

December 12, 2024

Top 7 Waterproofing Materials for Concrete Roofs

December 13, 2024

Search This Blog

MUST READ

What is PERT? Objectives, Pros & Cons

September 10, 2017

Terzaghi's Equation: Soil Bearing Capacity for Foundations

March 02, 2022

Contact Form

Footer Menu Widget

Created By SoraTemplates | Distributed By Gooyaabi Templates

.jpeg)

0 Comments

Commenting Spam Links Are Against Policies