Search This Blog

Most Popular

Sieve Analysis of Aggregates - ASTM Standard

August 11, 2021

What are Inclined Columns?

January 30, 2017

Categories

- Building Construction (82)

- Building Materials (82)

- Columns (2)

- Concrete Beam (3)

- Concrete Construction Techniques (4)

- Concrete Mix Design (10)

- Concrete Repair (14)

- Concrete Slab (10)

- Construction Equipment (16)

- Construction News (7)

- Design of Structures (15)

- Engineering Drawing (1)

- Estimation (3)

- Geotechnical engineering (26)

- Highway Engineering (11)

- Innovations (30)

- Material Testing (9)

- Matrix Analysis of Structures (2)

- Mechanical Engineering (3)

- Strength of Materials (2)

- Structural Analysis (17)

- Structural Design (21)

- Structures (17)

- Transportation Engineering (9)

Modularization in Construction - Important Terms

Neenu

October 20, 2023

Modularization in construction is a modern method of construction (MMC) where major construction products and activities are conducted offsite followed by on-site installation. It is a comprehensive word provided for modular construction techniques.

A construction project can be completely or partly modularized based on the requirements and specifications. It is applicable where access to skilled labor is tedious like in remote areas or where traditional stick-built construction incurs large labor, equipment, supporting infrastructure, and related costs.

This article, discuss briefly on module design and engineering and the important terms associated with it.

Note💡Stick Built is a traditional construction method that is entirely performed at the site. It is the opposite of the modular construction.

Module Design and Engineering

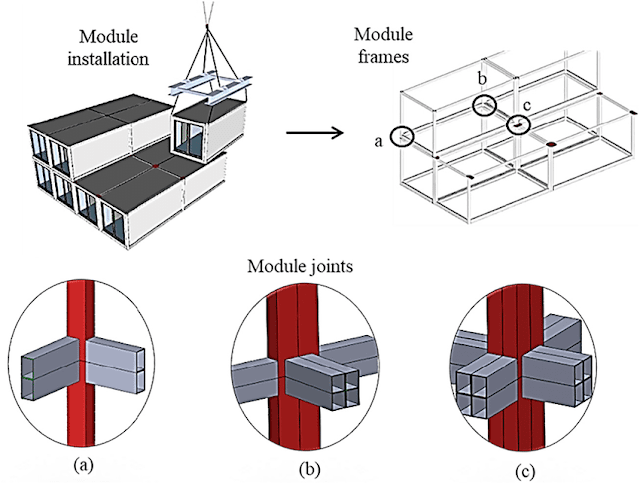

Module design and engineering involves working with modules that are pre-fabricated or manufactured at a module shop yard, tested, pre-commissioned, preserved, and transported to the site for installation and connections to other or existing modules to develop a complete facility unit. Every modular project demands a modularization plan at the beginning followed by module design, engineering, procurement, and construction.

This technology divides the whole project structure into small units or modules that are developed at a plant and joined together to make the real structure.

Definitions in Modularization in Construction

Some of the key terms associated with modularization are:1. Module

A module is a set of separated parts of a complete unit that is transportable and assembled fully or partly at the site. These modules minimize site installation and commissioning, labor costs.2. Types of Modules

Modules used in modular construction can be pre-assembled units (PAU), pre-assembled racks (PAR), pre-assembled buildings (PAB), and vendor-assembled units (VAU).- Pre-Assembled Building (PAB)

- Pre-Assembled Rack (PAR)

- Pre-Assembled Unit (PAU)

- Vendor Assembled Unit (VAU)

3. Module Yard

Module yard is a remote location away from the site that is employed for manufacturing, assembling, and installation of components.

4. Modularity

Modularity represents the degree of modular application for a particular project. A project may be conducted with a higher degree of modularisation remaining works performed by conventional methods. This is dependent on the cost and the location of the construction site.

5. Module Envelope Drawing

Module envelope drawing or module drawing index is the plan drawing depicting the individual breakdown modules, its technical details, and performance requirements for developing and selecting of design of each module for the project. It can be detailed drawings with specifications, vendor item control source control drawings, etc.

6. Optimum Module Size and Inclusions

Optimum module size mentions the appropriate size of the module that is designed based on project economics and the module handling capacity. In addition, the severity of the project like safety, quality, project duration, and environmental factors also influence the optimum module size.

The module handling capacity states the capacity of the module fabrication shop, the transportation of the module inland and ocean, its accessibility to the site, module erection capacity, labor, equipment schedule, etc.

7. Centre of Gravity (COG)

The Centre of gravity is defined as the point on the material where its whole mass tends to act. In the case of uniform material, it will be in its center. This concept of center of gravity (COG) is employed for the weight control work process for module design and engineering for the transportation and installation at the site.

Determining the COG of each module facilitates safe design and proper installation of structural elements with proper balance.

Read More: Pros and Cons of Modular Construction

Most Visited

Sieve Analysis of Aggregates - ASTM Standard

August 11, 2021

How to Calculate Cement Required for Floor Tiling?

July 02, 2020

What are Infiltration Wells?

April 15, 2024

Cross-Section of a Road – Geometric Design of Highways

February 26, 2021

How to Choose Good Quality Aggregates for Construction?

August 10, 2021

Traverse Surveying - Objective, Method and Procedure

January 19, 2022

Construction ERP System – A Comprehensive Guide

December 12, 2024

Top 7 Waterproofing Materials for Concrete Roofs

December 13, 2024

Search This Blog

MUST READ

What is PERT? Objectives, Pros & Cons

September 10, 2017

Terzaghi's Equation: Soil Bearing Capacity for Foundations

March 02, 2022

Contact Form

Footer Menu Widget

Created By SoraTemplates | Distributed By Gooyaabi Templates

0 Comments

Commenting Spam Links Are Against Policies