بحث هذه المدونة الإلكترونية

Most Popular

Aerogel for Building Insulation - Beginners Guide

مارس 25, 2025

How to Heatproof Buildings with Resilient Materials?

مارس 24, 2025

Categories

- Building Construction (82)

- Building Materials (82)

- Columns (2)

- Concrete Beam (3)

- Concrete Construction Techniques (4)

- Concrete Mix Design (10)

- Concrete Repair (14)

- Concrete Slab (10)

- Construction Equipment (16)

- Construction News (7)

- Design of Structures (15)

- Engineering Drawing (1)

- Estimation (3)

- Geotechnical engineering (26)

- Highway Engineering (11)

- Innovations (30)

- Material Testing (9)

- Matrix Analysis of Structures (2)

- Mechanical Engineering (3)

- Strength of Materials (2)

- Structural Analysis (17)

- Structural Design (21)

- Structures (17)

- Transportation Engineering (9)

Glass Fiber Reinforced Gypsum (GFRG) Construction Material

Neenu

يناير 22, 2022

GFRG is Glass Fiber Reinforced Gypsum is a gypsum construction material that was initially developed from England to the United States and Canada in 1977, and came into use since 1990. The product is form of gypsum plaster reinforced with glass fibers to produce a thin, lightweight, and a stronger material. GFRG is also called as fiberglass reinforced gypsum (FRG) and Glass Reinforced Gypsum (GRG).

|

| GFRG Panel Building Construction Image Courtesy: Click.in |

GFRG is mainly used as an interior alternative for Glass Fiber Reinforced Concrete (GFRC). GFRC is mainly used for exterior applications.

We will discuss the composition, properties and various applications of GFRG in constructing a building.

Fabrication of GFRG

The composition of GFRG are:

- High-density alpha-based gypsum

- Glass fiber reinforcement

The gypsum plaster should be neutral or low alkaline to ensure its compatibility with "E" glass fibers. The additives commonly used with gypsum manufacturer's recommendations.

GFRG are manufactured as panels of thickness of 124 mm under careful controlled conditions to a length of 12 m and height of 3m. They are manufactured with cavities, that are unfilled, partially filled or fully filled with reinforced concrete as per the structural requirement and applications.

A good quality GFRG panels are selected based on:

- Zero-VOC alpha-gypsum mined in the USA

- Glass mat incorporated for strength

- ASTM testing including the all-important ASTM E84 (0/0 smoke/flame)

- 2.5 lbs./ft² high strength composition

- LEED supported

Applications of GFRG

The general category of applications of GFRG panels in building construction are:

- Load bearing walls

- Partition walls

- Compound and security walls

- Horizontal floor slabs or roof slabs

1. Load Bearing Walls

GFRG panels with cavities that are filled with reinforced concrete can be used as load bearing walls for multistoried housing. For single/two-storey construction, the cavities can remain unfilled or filled using structural core filling materials like insulation, quarry, dust, sand, polyurethane or lightweight concrete.

2. Partition Walls

Partition walls are used as multi storied frame buildings, that can be filled suitably. These walls can also be used for cladding installation for industrial or sport facilities etc.

3. Compound Wall Construction

Low and cheap compound walls or security walls can be constructed.

4. Horizontal floor slabs or roof slabs

Horizontal floor slabs or roof slabs with reinforced concrete micro beams and screed (T-beam action). This system can also be used in inclined configuration, like staircase waist slab and pitched roofing.

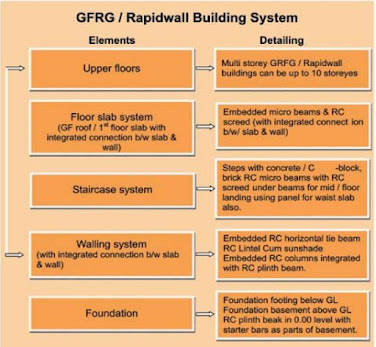

GFRG Building System

Mechanical Properties of Glass Fiber Reinforced Gypsum (GFRG)

Advantages of GFRG in Building Construction

The main advantages of GFRG in building construction are:

- Flame resistant

- Ease of installation

- Provide good finish

- Thermal resistant

How to get Quality GFRG?

A. Manufacturer’s Qualifications:

- Obtain GFRG from a manufacturer who will, upon request, send a qualified technical representative to the project site for the purpose of advising the installer of procedures and precautions for materials used.

- Obtain GFRG from a manufacturer who will certify the materials have been tested and proven satisfactory for the intended use.

- Obtain GFRG from a manufacturer with five years verifiable and successful experience producing material for projects of similar size and scope. GFRG must be manufactured in the United States.

B. Installer’s Qualifications:

- Firm must provide evidence of three years verifiable evidence installing the specified work.

- Installer must be acceptable to the manufacturer.

Tests on Characteristic Properties of GFRG Panels

- Tensile Strength - Tested as per ASTM Test Method D638-14

- Compressive Strength - ASTM Test Method C170 21.4 MPa

- Flammability - ASTM Test Method E84

- Barcol Hardness - ASTM Test Method D2583-13a

- Coefficient of Linear Thermal Expansion - ASTM Test Method D696

- Water Absorption - BS EN 520 : 2004 + A1:2009

Read More On: Building Construction Materials

Most Visited

Sieve Analysis of Aggregates - ASTM Standard

أغسطس 11, 2021

How to Calculate Cement Required for Floor Tiling?

يوليو 02, 2020

What are Infiltration Wells?

أبريل 15, 2024

Cross-Section of a Road – Geometric Design of Highways

فبراير 26, 2021

How to Choose Good Quality Aggregates for Construction?

أغسطس 10, 2021

Traverse Surveying - Objective, Method and Procedure

يناير 19, 2022

Plasticizers For Concrete - Principle, Types & Advantages

يوليو 23, 2021

Construction ERP System – A Comprehensive Guide

ديسمبر 12, 2024

Top 7 Waterproofing Materials for Concrete Roofs

ديسمبر 13, 2024

بحث هذه المدونة الإلكترونية

Footer Menu Widget

Created By SoraTemplates | Distributed By Gooyaabi Templates

0 تعليقات

Commenting Spam Links Are Against Policies