بحث هذه المدونة الإلكترونية

Most Popular

Categories

- Building Construction (87)

- Building Materials (88)

- Columns (2)

- Concrete Beam (3)

- Concrete Construction Techniques (6)

- Concrete Mix Design (15)

- Concrete Repair (14)

- Concrete Slab (11)

- Construction Equipment (17)

- Construction News (7)

- Design of Structures (20)

- Engineering Drawing (1)

- Estimation (3)

- Geotechnical engineering (26)

- Highway Engineering (11)

- Innovations (34)

- Material Testing (11)

- Matrix Analysis of Structures (2)

- Mechanical Engineering (3)

- Strength of Materials (2)

- Structural Analysis (13)

- Structural Design (24)

- Structures (17)

- Transportation Engineering (9)

How to Test Moisture Content of Floors and Slabs?

Concrete floors and slabs are the common subfloors used for flooring installations. This option can create issues if there is too much moisture in the concrete floors.

The concern of moisture hence demand tests to determine the moisture content of the sub-floor before installing any flooring or moisture barriers.

The article explains three standard methods used to determine the moisture content of the concrete surface.

Need for Concrete Moisture Test

The excess moisture in the concrete slabs or floors get trapped as such when covered by an impermeable cover. With time, the moisture trapped exerts hydraulic pressure upwards, causing bubbles in the surface treatments. These finally results in cracks on the covering materials installed above it.

A lot of water is released into the atmosphere during the hydration process of the concrete. As time passes, the vapor pressure of the concrete slab decreases relative to the atmosphere's vapor pressure. When the concrete dries to a point where the air is moist than the slab, the hydration pass back to the concrete. Hence, it is recommended to pour concrete when the concrete's vapor pressure and the air are in equilibrium.

Moisture Test on Concrete Slabs and Floors

The three main tests used to perform a moisture test on concrete slabs are:

- Plastic Sheet Test (ASTM D 4263)

- Relative Humidity Test using Probes ( ASTM F 2170)

- Anhydrous Calcium Chloride Test ( ASTM F 1896)

1. Plastic Sheet Test

The plastic sheet test involves the procedure of taping the concrete surface with a plastic sheet. Thus it creates a vapor-proof seal around the installed plastic.

The sheet is kept in place for 72 hours. After 72 hours, the moisture level under the plastic sheet is measured using a hygrometer. The measurement gives the extend of evaporation that happened within the past 72 hrs.

The method was developed by ASTM international and provided in the standard code ASTM D 4263.

2. Relative Humidity Test Using Probes

The test involves the insertion of an electronic meter into the concrete floor. It can be inserted through a hole drilled in the concrete floor. The meter must be embedded before the concrete finish curing.

The instrument measures the relative humidity over a period of 72 hrs. The information determines the amount of moisture present through the core of the slab.

The ASTM international has standardized the test in ASTM F 2170.

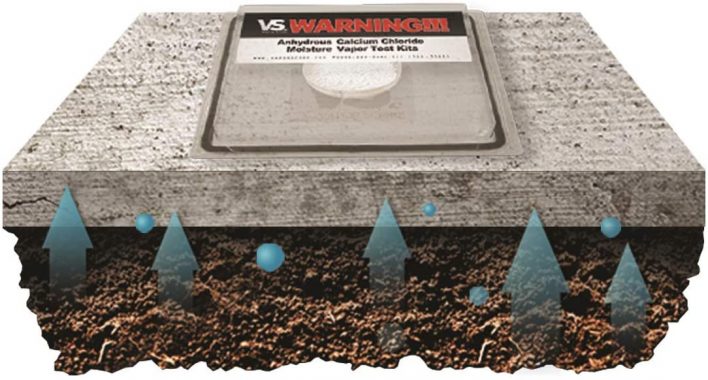

3. Anhydrous Calcium Chloride Test

The test is followed as per ASTM F 1896. The test makes use of a sealed surface to trap moisture, unlike the plastic sheet test.

The test is performed in three locations for every 1000sq.ft of the concrete slab. This way, the moisture level across the complete concrete floor is determined. The test is hence not limited to a particular area.

A packet of dry calcium chloride is poured into a container and weighed. The container prepared is placed in one of the locations. A plastic enclosure is used to seal the container. Place different similar containers at different locations.

After 72 hours, the containers are removed and weighed again. The excess weight indicates the number of moistures absorbed by the crystals during the evaporation of concrete.

The information hence helps to calculate the pounds of water vapor that is released per 1000 square feet across the whole concrete surface.

The vapor emissions exceeding 3 pounds per 1000 feet is not recommended.

The surface vapor test gives the moisture amount released at the surface, and the embedded probes test the moisture within the slab. Both the test gives the moisture level in the concrete floor. As the condition of the slab varies with time, the mentioned tests must be repeated several times.Read More:

0 تعليقات

Commenting Spam Links Are Against Policies